- “Revolution in factory planning”: NVIDIA Omniverse enables virtual

production in Plant Debrecen more than two years before actual

series production is launched - New dimension of BMW iFACTORY: Faster, more efficient planning

processes save time and costs - Global rollout of virtual planning

- BMW AG Board Member for Production Milan Nedeljković and NVIDIA

CEO and founder Jensen Huang deliver joint demo at GTC 2023

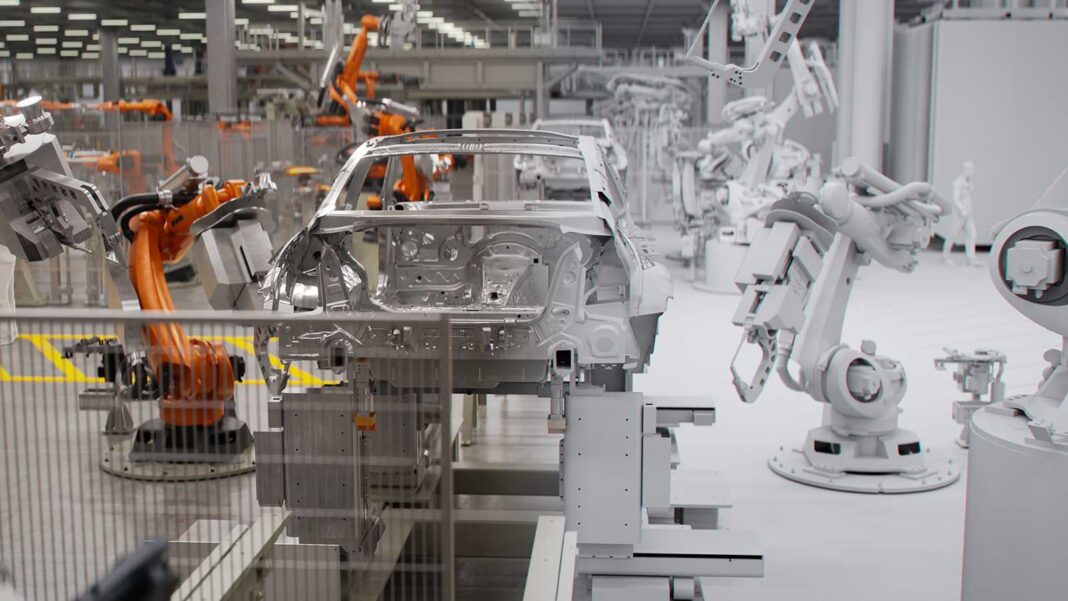

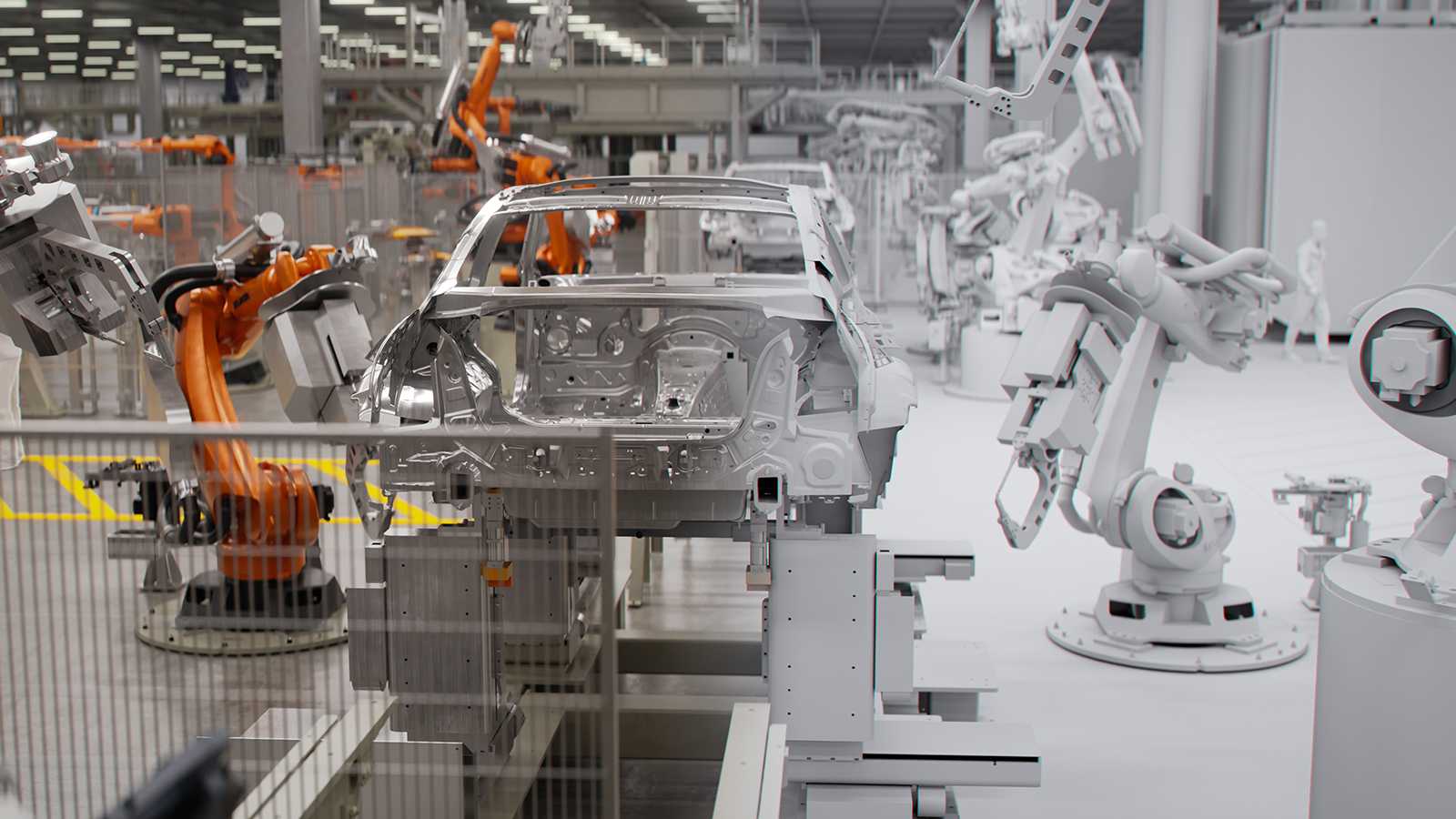

Munich. BMW Group has taken factory planning to new

heights – setting the latest milestone in the digitalisation of

automotive manufacturing. More than two years before the official

launch of series production, vehicle manufacturing is already underway

in the future plant Debrecen – virtually, at least, as Debrecen is the

BMW Group’s first facility to be planned and validated completely

virtually. The ground-breaking and innovative planning concept was

realised in collaboration with its partner NVIDIA. The future plant

Debrecen is scheduled to open in 2025. Construction has just begun,

and the new facility is scheduled to produce the BMW Group’s next

generation of all-electric models: the Neue Klasse.

BMW Group is taking a digital-first approach to validate and optimize

complex manufacturing systems across its production network using

NVIDIA Omniverse Enterprise, a platform for building and operating 3D

industrial metaverse applications, to run real-time digital twin

simulations to optimise layouts, robotics and logistic systems

virtually. Omniverse will be extended across the BMW product network

around the world.

“Virtualisation and artificial intelligence are accelerating and

refining our planning. With the various planning systems consolidated

within a digital twin, our teams around the world can now work

together in real-time and make decisions faster and on a more solid

foundation,” Milan Nedeljković explained. “This makes us much quicker

and more efficient and saves on costs as well.”

“Digitalization is moving fastest in the automotive industry and BMW

has been a leader in advancing this vision,” said Jensen Huang,

founder and CEO of NVIDIA. “We are partnering closely with BMW, using

NVIDIA Omniverse to help streamline their manufacturing processes,

enhance collaboration and further efficiency. Our collaboration will

continue to push the frontiers of virtual integration for the next

generation of smart, connected factories around the world”.

In a joint demo at the NVIDIA GTC, a global conference for the era of

AI and the metaverse, Milan Nedeljković, took Huang on a virtual

planning session for the new body shop. Nedeljković described the

real-time collaboration between the different BMW Group planning

departments and their partners as a “revolution in factory planning”,

delivered on NVIDIA’s Omniverse – which had enabled the first virtual

start of production.

Engineering and planning experts from the two companies, both leaders

in their respective fields worked, in close collaboration to help BMW

build Omniverse applications that meet the BMW Group’s specific

requirements. The virtual planning approach for the new vehicle plant

is now considered a blueprint for all future planning processes at the

BMW Group.

Virtual planning facilitates global collaboration – rollout

starts end of March

NVIDIA Omniverse makes collaboration across sites and time zones

easier and supports the planning and design of structures, production

systems and processes at an entirely new technological level. It works

as a “cockpit”, offering quick, easy access to the digital planning

worlds of BMW. At the end of this month, Omniverse, which is both

cloud-based and cloud-agnostic, will be available to BMW experts in

various technologies and planning departments.

Next milestone in the BMW iFACTORY

Consistent virtual planning of highly complex vehicle production

processes represents the BMW Group’s next important step in the

transformation to the BMW iFACTORY. First introduced in early 2022,

the concept of the iFACTORY is described by Nedeljković as “our

masterplan for the automotive production of tomorrow”.

Based on a completely new vehicle architecture, the Neue Klasse

heralds the fundamental transformation of production to the BMW

iFACTORY. It began in 2020, when all of the BMW Group’s vehicle and

engine plants were 3D-scanned. Since November of that year, more than

seven million square metres of indoor and 15 million square metres of

outdoor production space have been scanned. Subsequent modifications

can be integrated into the digital world with a re-scan, to ensure the

available data is always up to date.

Meanwhile, virtual planning is under way for the roughly 1.4

km2 production hall for the Neue Klasse in Debrecen, where

the success of the virtual start of production is a testament to the

high standards that can be achieved through the digitalisation of the

planning process. NVIDIA Omniverse allows production experts to use

live data both in-house and with suppliers on the detailed planning

and optimisation of processes and individual systems – without

compatibility issues. It makes structure and facility data easy to

retrieve and integrate with equipment and assembly line data. In the

future items and part numbers for production materials will be

available as well. What’s more, layout options – for instance for

robots in work cells, or for the various areas of logistics – can be

played through in real-time, photorealistic simulations and adapted as

required. And with Omniverse, any modifications are evaluated,

validated and implemented in real-time. The platform also will allow

suppliers to be involved in decision-making and integrates the

tried-and-tested design and planning tools that BMW has been using to

date. These are made by various producers and include Bentley Systems

MicroStation for layout planning, ipolog for logistics planning,

Siemens Process Simulate, Dassault Systemes CATIA for vehicle design

and Autodesk Revit for building planning, with more tools to follow.

Over time all the relevant product, process, quality and cost data

will also gradually be available in Omniverse alongside the

development, planning and production processes. There will also be

further developments to the platform, which are expected to include

“invisible” processes such as the consumption of energy and resources.

Omniverse will enhance digital operations as well – a crucial stage

that is already being tackled by BMW Group and NVIDIA teams. In the

future, this will allow operational faults to be localized in a matter

of seconds and thus prevent longer production downtimes. It is also an

important step towards, for example, integrating and automating

virtual commissioning of new systems into a continuous planning process.

![[Presentation] Livestream of TMC’s Press Conference](https://www.miamicars.com/wp-content/uploads/2023/02/tmb_corporate-218x150.png)